Compliance with BCGA Codes of Practice

The safe use of compressed gas equipment is a legal requirement for any workplace. Engweld provides certified inspections to help you meet the compliance demands of the Health and Safety at Work Act 1974 and the Pressure Systems Safety Regulations (PSSR).

Principal Codes of Practice - British Compressed Gases Association (BCGA)

BCGA CP7 - The Safe Use of Oxy-fuel Gas Equipment

Cylinders, Gas Regulators, Gas Hoses, and Torches used for Oxy-Acetylene and Oxy-Propane welding, heating, and cutting.

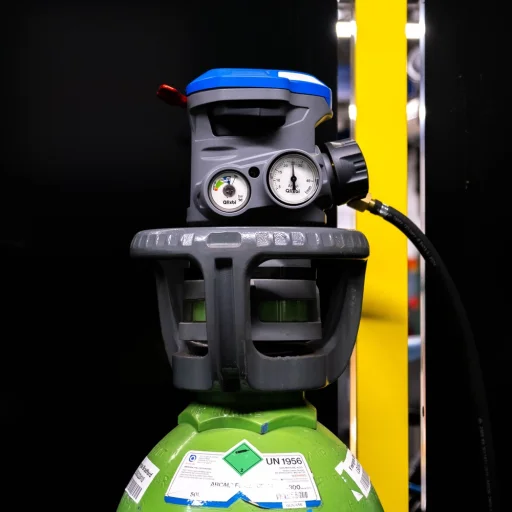

BCGA CP47 - The Safe Use of Individual Portable or Mobile Cylinder Gas Supply Equipment

Single-cylinder systems used for MIG/MAG Welding and TIG welding with inert or mixed gases (e.g., Argon, CO2, shielding gas mixtures) and single-use propane systems.

The BCGA recommends that regulators and flashback arrestors are checked annually and must be replaced by the manufacturer's recommended replacement date.

Qualified Inspectors for Dual Certification

Our comprehensive gas equipment safety checks are carried out by our own fully trained and qualified inspectors, who hold certification to both BCGA CP7 and BCGA CP47 standards and operate in strict accordance with HSE guidance (INDG 381).

The inspector is proficient in the theoretical knowledge of equipment functioning, gas properties, and the importance of identifying potential defects and hazards, ensuring your system is safe and compliant.

What Our Inspection Includes

Our rigorous inspection covers all key components of both CP7 and CP47 systems, including:

| Inspection Area | CP7 (Oxy-Fuel) Checks | CP47 (Inert/Single Cylinder) Checks |

|---|---|---|

| Regulators | Visual inspection, leak and functionality testing. | Visual inspection, leak and functionality testing on single and multi-stage regulators. |

| Flashback Arrestors | Visual inspection, leak testing, and reverse flow tests to ensure correct operation. | Visual inspection, leak testing, and reverse flow tests (where fitted) to ensure correct operation. |

| Hoses & Fittings | Inspection for damage, wear, leaks, and correct selection and use of hose assembly. | Inspection for damage, wear, leaks, and verification of correct hose selection and secure fitting to the regulator. |

| Blowpipes/Torches | Checks for leaks, damage, and correct operation. | N/A (Focus is on the cylinder pressure equipment up to the gas delivery point). |

| Documentation | A comprehensive written Report of Thorough Examination detailing the findings. A Certificate of Inspection is issued upon successful compliance. |

How to Order Your Gas Inspection(s):

- Check Service Area: Use your postcode below to confirm we offer CP7 & CP47 gas inspections in your area. (Keep the list of covered postcodes visible).

- Complete Questions: Answer the following questions, ensuring you correctly identify the gas systems you need checked.

- Checkout: Add the relevant gas inspection(s) to your basket and complete the checkout process.

Crucial Update for the Fuel Type Question:

The inspection you receive is based on the equipment you operate.

Which fuel type are you using?

- Oxy-Acetylene (CP7 Inspection)

- Oxy-Propane (CP7 Inspection)

- Single use propane (CP47 Inspection)

- Inert (MIG/TIG) (CP47 Inspection)

(Retain the number-of-stations questions for each type, as they are essential for quoting.)

Important Note on Remedial Work

Please note: There may be additional charges which you need to pay for if it is found that equipment or parts need to be replaced. The gas inspection engineer will inform you of this once the inspection is complete, but these would need to be paid for over the phone with your local branch before the engineer leaves.