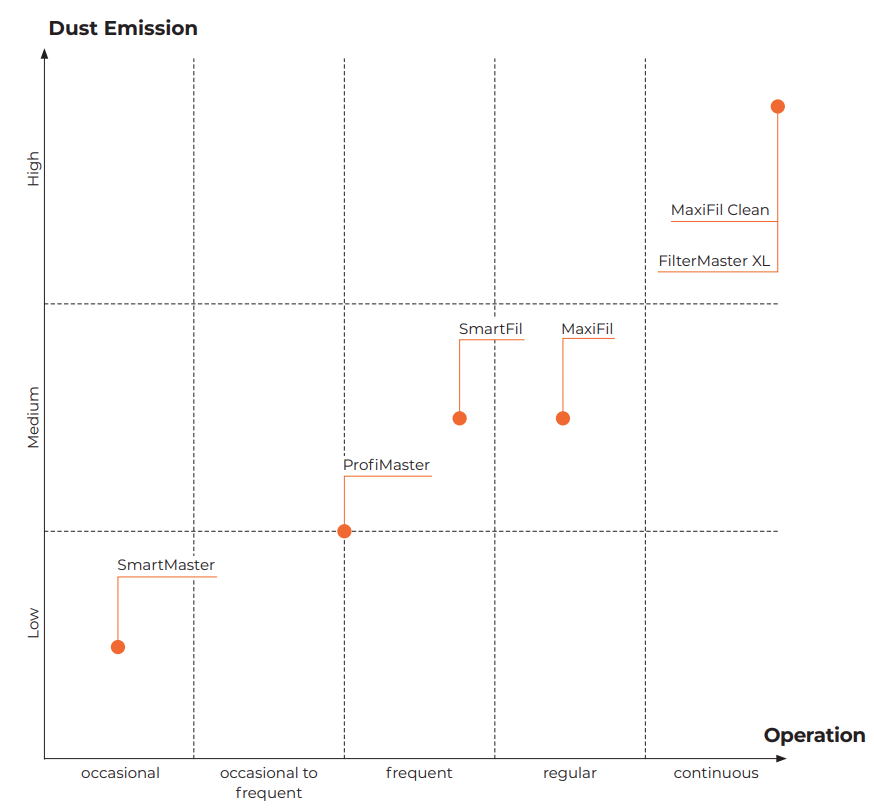

Kemper is a well established brand and a leader in the field of welding fume extraction with over 40 years of experience. The brand 6 different mobile welding fume extraction units and this guide will help you choose the right one for your application. All content including graphs and data has been taken from Kemper.eu.

Range of application

| SmartMaster | ProfiMaster | SmartFil | MaxiFil | Filter-Master XL | MaxiFil Clean | |

| High-alloy steel non-ferous metal (IFA) | x | x | x | x | x | x |

| TIG welding Chromium nickel steel | x | x | x | x |

Comparative Test

Testing conditions

Welding current: 312 A | Welding voltage: 30.3 V | Wire diameter: 1.2 mm | Wire feed: 11 m/min

| Model | Recommended application | Filter surface | Welding time in hours (Arc time) | Usage of welding wire (kg)* | Filter life (Factor) |

| SmartMaster | Occasional | 13 m² | 6 ¾ | 40.7 | 100% |

| ProfiMaster | Frequent | 17 m² | 13 | 86 | 210% |

| SmartFil | Frequent | 25 m² | 20 | 114 | 280% |

| MaxiFil | Regular | 42 m² | 33 ¼ | 218 | 540% |

Note:

- The results were established by extensive durability test on an automatic welding system.

- The lower the filter surface, the higher is the airspeed across the filter media. The particles form a solid filter cake and the flow through the filter media is restricted. The dust load capacity is very poor.

- The higher the filter surface, the lower is the airspeed across the filter media. Particles form an open porous filter cake which acts as an additional filter. The air can flow through the filter cake and the filter media easily for a long time. The dust storage capacity is very high. This is the reason for the much longer filter life of the MaxiFil.

If you have any questions or need help in choosing the right welding fume extraction solution for your application, please contact us and speak to one of our experts. Technical advice and on-site demonstrations are available from all our sales centres. Engweld also stocks all spares & filters for the above fume extraction solutions.