Making positive changes to reduce environmental impact is becoming ever more important in modern life and this is now present in our laws and regulations.

In January of 2021, new EU regulations came into effect concerning the ecodesign requirements of welding equipment and the environmental impact of welding such as the amount of energy being consumed during the welding process. The regulations state that the key environmental aspects of welding equipment in relation to energy consumption are: ‘energy consumption in the use phase, including when the products are in ‘idle’ mode’ and ‘resource efficiency aspects’.

How much energy does welding use?

The regulations estimate that by 2030, the annual final energy consumption directly related to welding equipment is expected to be in excess of 6 TWh. To put this into environmentally damaging terms, this energy consumption equals around 2.4 million tonnes of CO2 equivalent. If this figure were not shocking enough, it should also be taken into account that this excludes the amount of energy used in making welding consumables like wire and shielding gases.

As well as being an energy intensive process, welding typically generates a large amount of fumes which can be harmful to the welder if proper safety precautions are not in place and to the environment.

It is essential therefore that your business and its processes meet these requirements.

What are the regulations?

The regulations cover three main areas, energy efficiency requirements, resource efficiency requirements and information requirements.

Energy Efficiency Requirements

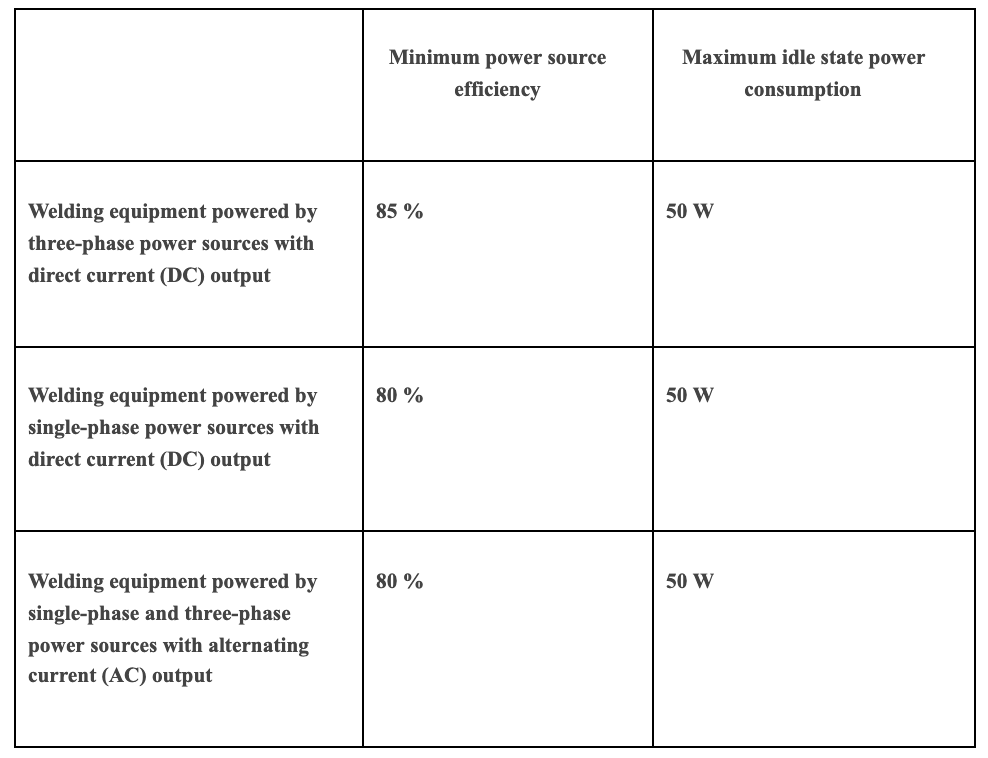

To meet the energy efficiency requirements specified, welding equipment must be in-line with the power source efficiency and idle state power consumption limits detailed in the table below:

Resource efficiency and information requirements

Businesses are also expected to adhere to the updated resource efficiency requirements around the availability of spare parts. Distributors such as Engweld are required to have the resources available to replace any spare parts such as control panels, equipment housing and gas supply regulators that you may need for a minimum period of 10 years after the production of the unit.

These parts shall indicate the use of welding wire or filler material in grams per minute or equivalent standardised units of measurement. Parts manufacturers must also make sure that any spare parts can be replaced with the use of common tools and without any permanent damage to the equipment and the part.

The updated regulations also allow you to gain access for anyrepair and maintenance information that you need through publicly available lists. All distributors, including Engweld, now have to state the power source efficiency and power source consumption of a part, making it easier for you to ensure that your welding equipment is eco-friendly and compliant with these EU regulations.

What do the regulations mean long term?

Following these regulations means there will be tangible benefits in terms of energy saved and reduced CO2 emissions. As the new ecodesign measures are being put in place, by 2030 it is estimated that these will save an average of 1,09 TWh or 0,27 Mt CO2 equivalent every year which not only is better for your business, but is also great news for the environment.

For the full breakdown of the EU requirements regarding eco-friendly welding equipment, visit: https://eur-lex.europa.eu/eli/reg/2019/1784/oj